|

Ceramic insulator grinder retrofit

- In 1995. we were engaged to make full retrofit

of a ceramic insulator grinder control system retrofit.

- Old electronic control system was implemented

on germanium transistor elektronic produced by German factory Zeidler in 1972.

- Our task was to design end realise a new

control system based on microctroler electronic and

Bosch servo hydraulic control devices.

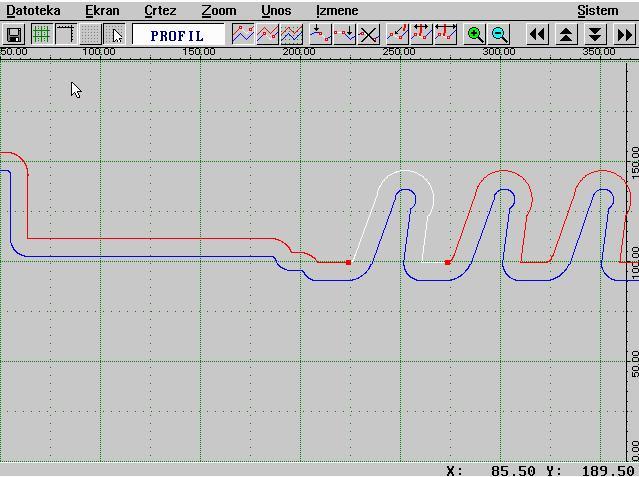

- Grinder control system was based on photo copy method.

Factory had a lot of papper draw of insulator design.

- Upon owner request we save photocopy system in work but

all other control system elements were fully redesigned.

- Retrofit was done under full UN economic

sanctions implemented to Serbia.

Insulator designer software

- Durring a retrofit proces, as a plus, we designed a insulator designer software.

- It was application design under MS-DOS, but in full XVGA graphics.

- Full desing process were implemented. Application generated insulator geometry, together with cutting knife roadmap.

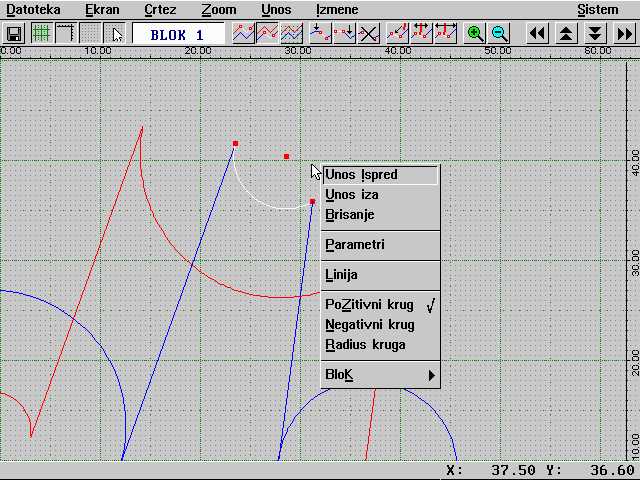

- Also, there were a realitme simulation of cutting knife job.

- It was an early specific fully implemented CAM system.

- As a final result, application prints whole insulator papper model ready to implement on grinder photo copy device

Some technical data

- Full electric insulator design up to four meter long high voltage insulators.

- Full graphics user interface with popup menus. icon based toolbar and dialog system.

- Database of cutting knives shapes.

- Design of sprite block design ready to combine and repeat.

- Print the papper design on multipage system.

- Whole software wad writen on Microsoft C 6.1 for MS-DOS 3.3

- After this project ICS&mc turn on Windows system programing.

|

|